FOOD & BEVERAGE

- BOTTLED WATER FILTRATION -

In the food and beverage industry, one small contamination can cause serious health issues and ruin your business. With Strainrite filtration systems, you won’t have to worry about contamination or leaks. Instead you’ll benefit from streamline systems engineered for easy, efficient use and better results.

INCOMING WATEREVP Filter Bags

|

MICRO-FILTRATION

|

MICRO-FILTRATION

|

CLEAN-IN-PLACEPoly-MAXX & Bev-MAXX Filter Cartridges

|

- SPORTS DRINK & JUICE FILTRATION -

|

- INCOMING WATER -

POLY-MAXX

|

|

- MICRO-FILTRATION PRE-FILTER -

POLY-MAXX

|

- PURIFICATION -

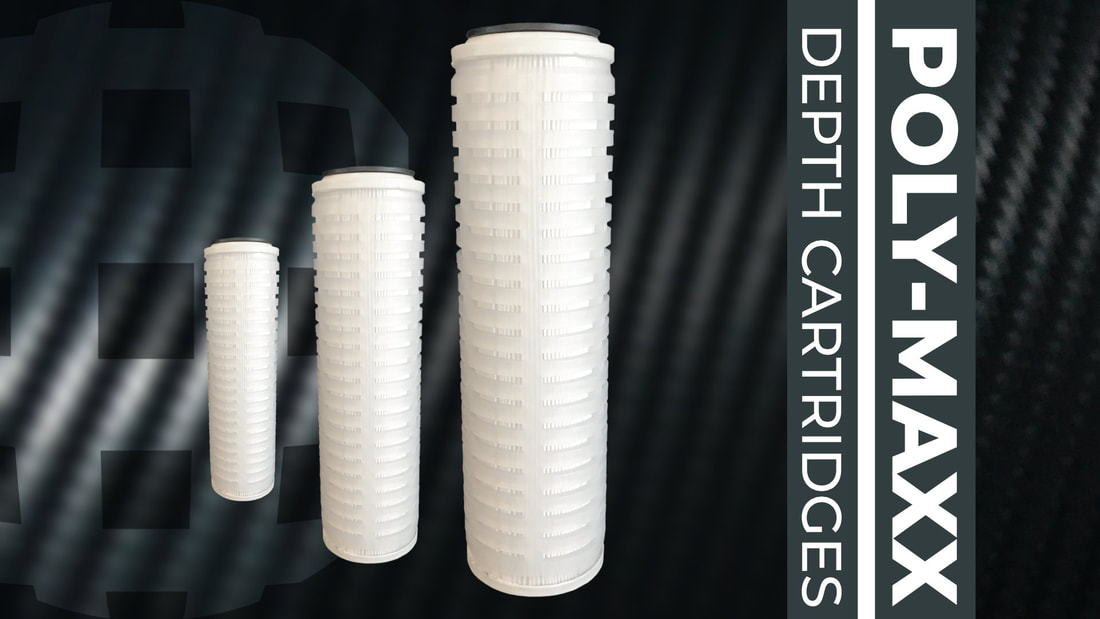

POLY-MAXX DEPTH CARTRIDGES

PUR-MAXX E PES MEMBRANE CARTRIDGES

|

Food & Beverage

In the food and beverage industry, one small contamination can cause serious health issues and ruin your business. With Strainrite filtration systems, you won’t have to worry about contamination or leaks. Instead you’ll benefit from streamline systems engineered for easy, efficient use and better results.

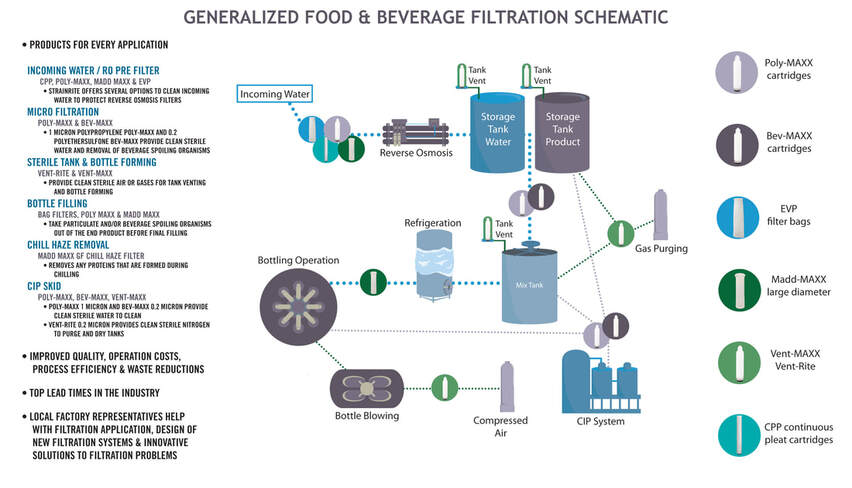

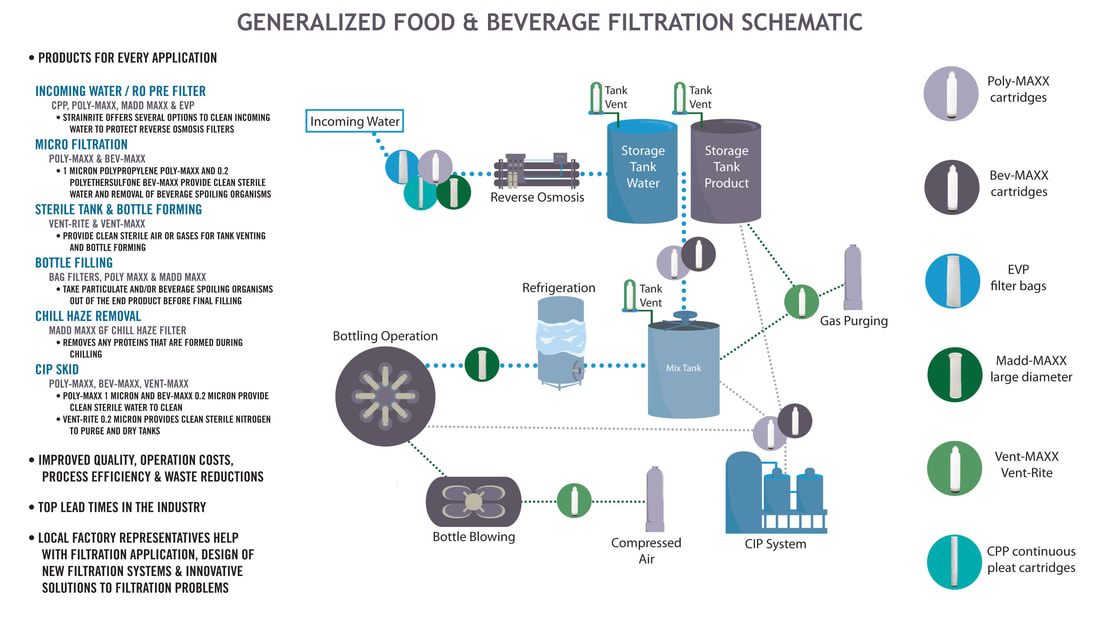

BOTTLED WATER FILTRATION

Incoming water

EVP filter bags

Micro-Filtration

Pre-Filter Poly-Maxx filter cartridges

|

|

Micro-Filtration Final filter

Bev-Maxx filter cartridges

|

Clean-In-Place

Poly-Maxx and Bev-Maxx filter cartridges

|

SPORTS DRINK / JUICE FILTRATION

|

Incoming Water

Poly-Maxx filter cartridges

|

Micro-Filtration Pre-Filter

Poly-Maxx filter cartridges

|

Micro-Filtration Final Filter

Bev-Maxx filter cartridges

|

|

Tank Vent

Vent-Maxx PTFE filter cartridges

|

Bottle Forming

Vent-Maxx PTFE filter cartridges

|

CIP Skid

|

Poly-Maxx filter cartridges

|

Pur-Maxx ESG filter cartridges

|

Vent-Maxx PTFE filter cartridges

|

SPIRIT FILTRATION

|

Incoming Water

EVP filter bags

|

Main Fill

Maxx-Flow large diameter pleated cartridges

|

Trap Filters

Maxx-Trap large diameter pleated cartridges

|

|

Chill Haze

Madd-MAXX GF large diameter pleated cartridges

|

Pre-Final Filter

Guard-Rite filter cartridges

|

Clean In Place

In the food and beverage industry, one small contamination can cause serious health issues and ruin your business. With Strainrite filtration systems, you won’t have to worry about contamination or leaks. Instead you’ll benefit from streamline systems engineered for easy, efficient use and better results.

|

Hot Water & Steam Sterilization

Holding Tanks / CIP System Air

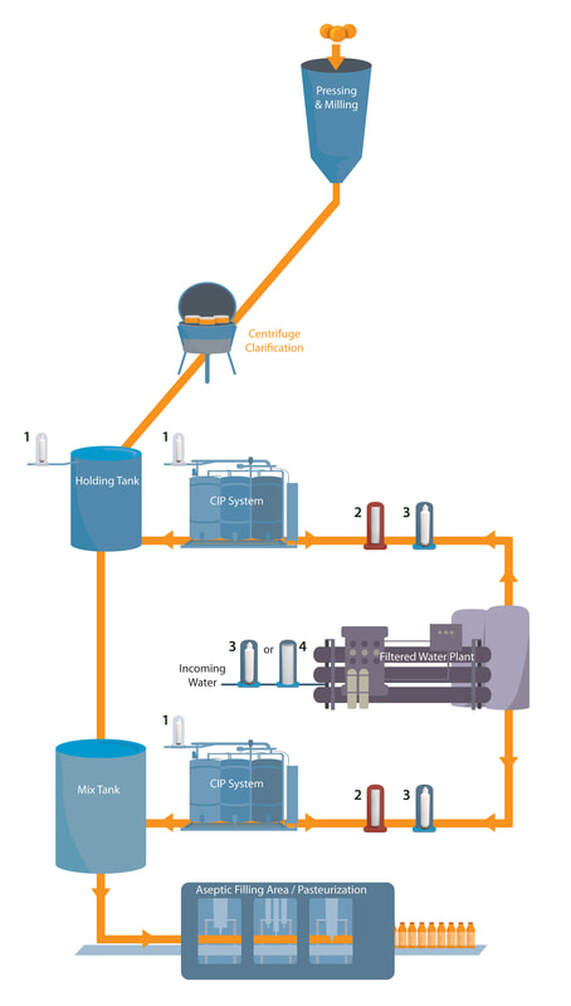

For filtration of holding tanks and CIP System air, Strainrite recommends the Vent-MAXX Cartridge (1). The Vent-Maxx gas sterilizing filters set a new standard for PTFE membrane elements. These filters utilize a technologically advanced membrane in our unique pleat construction to deliver unrivalled efficiency, superior strength, and high flow rates. Mix Tank For filtraton and pre-filtration of the mix process, from your CIP System to filtered water, Strainrite recommends as a pre-filter the Pur-MAXX ESG Cartridge (2). The Pur-MAXX E-SG is engineered to meet the highest standards of microorganism control for sterile fluids. Validated for complete removal of Brevundimonas diminuta (ATCC 19146) at test concentrations of 107 CFU/cm2, this product is ideally suited for applications where microorganism contamination causes product defects or extra processing time due to increased fluid instability. For further filtration protection a secondary Poly-MAXX (3) cartridge may be installed. More information on the Poly-MAXX can be found below. Incoming Water Incoming water should be free of any particles or sediments. Particles need to be removed from any water entering the mix process. For the highest quality, pure, clean water, Strainrite offers the Poly-MAXX (3) or the MAXX-Flow (4). The Poly-MAXX all-Polypropylene, filter cartridges are designed to optimize throughput while achieving absolute and repeatable effluent quality. Our filter media is constructed on the latest continuous Micro-Fiber blowing equipment that accurately controls fiber diameter and integrity. Utilizing state-of-the-art on-line monitoring equipment, Strainrite delivers the industry's most uniform and consistent media, ensuring unparalleled product consistency. Maxx Flow filters offer unique large pleat geometry making them capable of handling up to 500gpm in a 60˝ length, which is a perfect solution for high flow rate applications. These inside-out flow elements have higher dirt holding capabilities and offer hygienic superiority over typical outside-in fluid filtration filters. |

Filtration Systems for Viticulture

From Bordeaux to Napa and everywhere in between, nothing quite makes a dining experience like a fine glass of wine. For centuries, winemakers have picked and sorted grapes, fermented them in barrels, and aged them to perfection. Before these reds, whites, and roses can make it to your table however, they need to go through a stringent filtration process. That’s where we can help.

|

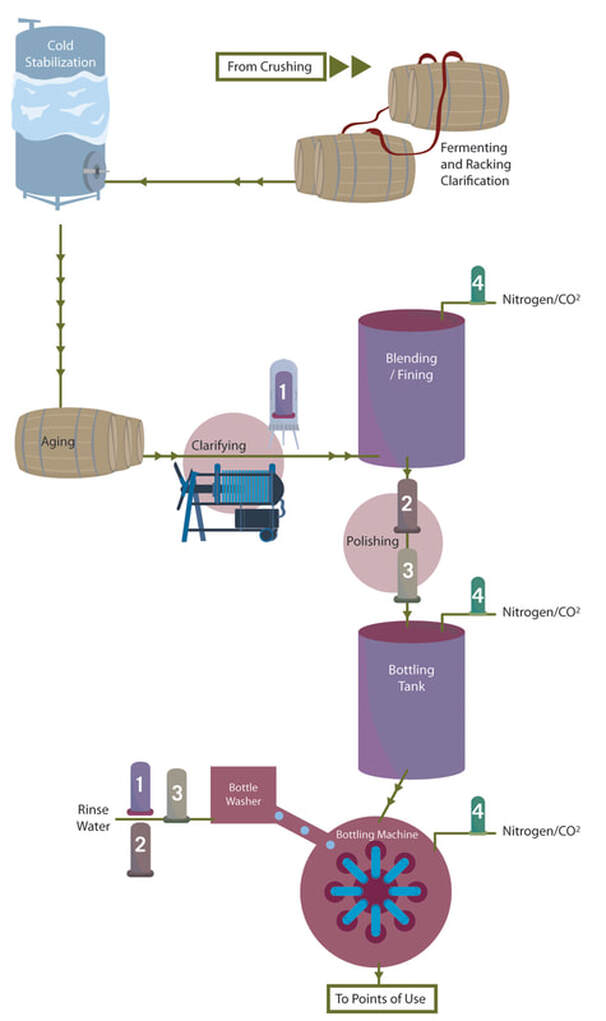

Clarifying

In wine tasting, a wine is considered “clear” when there are no visible particles suspended in the liquid and when there is no “haze.” A wine with too much suspended matter will appear cloudy and dull. Wine may clarify naturally as a result of gravity, with heavier particles settling at the bottom of the barrel. The wine can then be siphoned or “racked” off into a new container. But this process can take anywhere from months to years, as well as several rackings, in order to produce a clear wine. Filtration accelerates the process. For Clarifying, Strainrite offers the MAXX-Trap in a large diameter or the Fiber-MAXX, Fiber-MAXX G and Poly-MAXX G in a cartridge (1). Fining, Polishing & Stabilizing A fining agent, usually gelatin, removes tannins and some microscopic particles. Gelatin reacts with the wine components as it clarifies, and forms a sediment which is removed by filtration prior to bottling. Filtration adds polish by improving a wine’s appearance, reducing a wine’s aging time, reducing excess levels of tannic acid and other proteins and reducing the chance of re-fermentation in the bottle. Many wines require the removal of all potentially active yeast or lactic acid bacteria if they are to remain reliably stable in the bottle Fine filtration accomplishes stabilization. Microbial stabilization requires a filtration of at least 0.65 μm for yeast retention and 0.45 µm for bacteria retention. Strainrite's Guard-Rite (2), Poly-MAXX Select (3) and Vino-MAXX E (3) are recommended for these crucial processes Bioburden Reduction & Sterilization Before bottling, wine bottles must be rinsed with filtered water. A membrane prefilter with pore sizes of 0.80µm to 1.2µm captures the bulk of harmful organisms and protects the critical final filters from being overloaded. Created for Beverage Pre-final filtration, the Guard Rite (2) is the pre-final filter to cost effectively reduce Bio-burden before final filtration and packaging. With a depth layer and synchronized final filtration layer optimized to extend final filter life with a stainless steel insert for steam or hot water sanitization. |

Process Gas

Normal atmosphere can cause microbial growth and oxidation. Normal air is replaced in holding tanks with nitrogen or carbon dioxide. As the wine is bottled, process gas is injected into each bottle. Hydrophobic 0.22µm membrane filters assure that no particulates or bacteria are carried

by the gas to the wine.

The Vent-Maxx (4) gas sterilizing filters set a new standard for PTFE membrane elements. These filters utilize a technologically advanced membrane in our unique pleat construction to deliver unrivalled efficiency, superior strength, and high flow rates. Vent-Maxx double layer PTFE membrane filters are designed to remove microorganisms, particulate, and moisture in your most demanding air and gas applications.

Normal atmosphere can cause microbial growth and oxidation. Normal air is replaced in holding tanks with nitrogen or carbon dioxide. As the wine is bottled, process gas is injected into each bottle. Hydrophobic 0.22µm membrane filters assure that no particulates or bacteria are carried

by the gas to the wine.

The Vent-Maxx (4) gas sterilizing filters set a new standard for PTFE membrane elements. These filters utilize a technologically advanced membrane in our unique pleat construction to deliver unrivalled efficiency, superior strength, and high flow rates. Vent-Maxx double layer PTFE membrane filters are designed to remove microorganisms, particulate, and moisture in your most demanding air and gas applications.

Commercial Beer Filtration Systems

|

America’s brewing industry is rapidly growing. With over 5,000 breweries and counting across the country, beer making (and beer drinking) is evermore popular in America. From stouts, to pale ales, to sours and more, brewing fresh beer means filtering out excess particles during the brewing process. We can help you there. Our filtration systems produce quality results throughout the brewing process including:

For Incoming Water

Good beer begins with pure, clean water, free of any particles or sediments. At the first stage of this process, particles need to be removed from the water. Our Enhanced Vertical Pleat (EVP) filter is ideal for any brew volume. This filter rises above the competition with its high filtration performance, long life, and loading capacity, all for a great price. Carbon blocks help remove chlorine, organic flavor, and sediment from tap water. A trap filter will target any remaining carbon particles. With a 99 percent rated filter media for consistent and repeatable performance Madd-MAXX filters like the MAXX-Trap are a perfect fit for trap filtration. By retaining all contaminants inside the filter during change outs Madd-MAXX elements have higher dirt holding capabilities and offer hygienic superiority over typical outside in fluid filtration. Madd-MAXXX elements are capable of handling up to 500 gpm in a 60’ length which is a perfect solution for high flow rate application. For Mashing During the mashing process, milled grain is steeped in hot water. This process activates malt enzymes and converts grain starches into fermentable sugars. The mash is then separated into clear liquid wort and residual grain in a mash filter or lautering tun. After this step, the wort is transferred to the brew kettle, and must be filtered for waste grains. This process requires a high quality filtration system, to ensure only the compounds you want make it into your beer, and nothing else. We recommend the Strainrite NMO Monofilament Mesh Filter Bag for this process. NMO Monofilament Mesh Filter Bags are an ideal solution because they are:

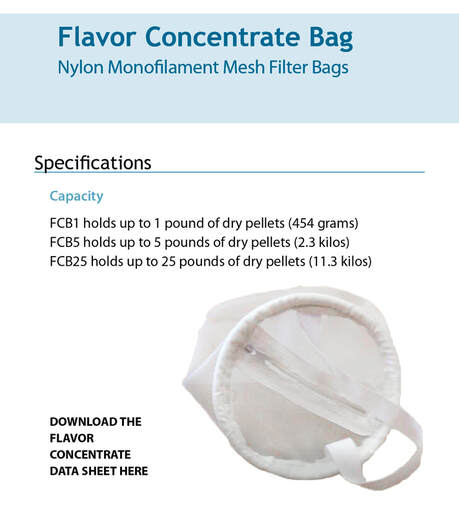

For Hopping The hopping process gives beer depth, balance, and signature flavors. Originally used as a preserving agent, hops are used for bittering, adding flavor or enhancing the aroma of beer. Hopping can take place at different stages of the brewing process, and for different intervals for different results. A few Strainrite filters we recommend to enhance this process include: The Strainrite NMO Monofilament Mesh Filter Bags, which catch boiling and finishing hops that are introduced during the brewing process. Strainrite’s nylon monofilament FCB (Flavor Concentrate Bag) reduce labor and material handling costs associated with dry hopping processes. Flavor Concentrate Bags come in three different sizes:

For Clarifying Clarifying is one of the final steps in the brewing process. Cooling beer encourages yeast and other suspended sediment to flocculate and sink. Then, the beer can be transferred from the fermentor for bottling, which eliminating chill haze in finished beer. For primary transfer prior to cold crashing, we recommend:

For microglass fibers in a large diameter cartridge, Strainrite recommends:

For Packaging Strainrite’s Fiber Maxx, MAXX-Flow GF and Madd-MAXX-GF also serve as an excellent final filters prior to kegging, bottling or canning, or as a pre-filter to final sterilizing filters. Brewers may opt for a final sterilizing filter just before final packaging, for which we recommend the Clarity line’s Bev-Maxx and Bev-Rite cartridges. These polyethersulfone, pleated filter cartridges are specifically engineered to provide an absolute barrier against beverage spoiling micro-organisms. |