Microelectronics & Semiconductor

Computing relies heavily on secure data storage, hard disk drives and cloud servers with nanometer-size, particle-free disk and drive surfaces capable of storing terabit levels of data. Critical liquid and gas applications require particle removal ratings from 0.02 to 40 micron. Strainrite offers highly effective filtration products designed for manufacturing data storage solutions such as hard-disk drives and cloud servers, with the right mix of particle retention to ensure optimal adhesion and defect-free results for processes including pre-sputter etch and clean, electroless nickel plating, wash processes, ultra-pure water, and disk lubrication.

Etch and Clean

Solvent-based lubes with low surface tension prevent stictional damage between the head slider and media and protect a media disk’s magnetic layers from corrosion. For fly heights less than 10 nanometers, the removal of nanometer-size particles crucially impacts disk reliability and performance. Strainrite filters provide superior particle removal with very low metal extractables. Strainrite filters also ensure disk surfaces are particle free in the pre-sputter etch and clean process, which utilizes DI water and dilute acids, prepares aluminum disk surfaces for nickel plating and ensures a particle-free substrate before zinc application.

Wet Process

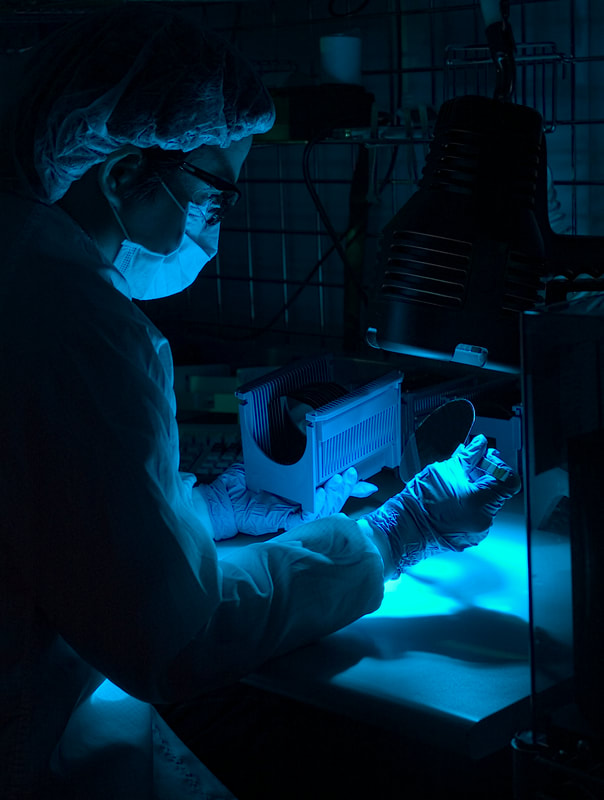

Strainrite products are specially designed to remove impurities in all critical, wet front- and back-end semiconductor processes, including single wafer etch and clean, batch wet etch and clean, single-pass chemical distribution systems, ECD copper plating and RO/DI filtration. Single-wafer wet processing involves dispensing concentrated or dilute process chemistry onto the surface of the wafer, often with lower flow rates and process temperatures in comparison to similar batch wet etch and clean processes. Batch wet etch and clean processes involve the processing of multiple wafers simultaneously. Wafers are typically immersed in a multi-pass process, and the process chemistry is recirculated repeatedly, typically requiring higher flow properties of cartridges. Strainrite cartridges and capsules are available in a variety of sizes to maximize single wafer etch and clean, offer high flow properties and high particle removal efficiencies for batch wet etch and are capable of high quality filtration in the widest range of aggressive and high-temperature wet processes. Chemical distribution systems deliver chemicals to production tools used for wet processing. Wet process chemical is usually pumped through filters into a day tank, typically requiring low, single-pass filters. Strainrite filters, designed for single or minimal pass systems, are optimized for the highest particle removal efficiency. ECD Plating Electrochemical deposition copper (ECD) plating deposits a thin uniform layer of copper on to the surface of a wafer. Strainrite’s hydrophilic filters achieve the best process results and are available in different lengths to fit both high flow recirculated plating processes as well as low flow single wafer plating applications. DI Water Semiconductor manufacturing processes must have access to large volumes of high-quality 18 megohm deionized water for blending chemistries and in critical wash steps. Strainrite depth filters offer the best protection to reverse osmosis systems, and Strainrite membrane filters rated down to 0.02 microns in point-of-use rinse applications. |

|

Strainrite's PES-E:

THE PES-E WAS DEVELOPED FOR MICROELECTRONICS INDUSTRY WHERE A HIGH DEGREE OF PARTICLE RETENTION AND/OR CONSTANT BACTERIAL BARRIER FOR EFFECTIVE STERILIZATION IS REQUIRED. HYDROPHILIC ASYMMETRIC POLYETHERSULFONE MEMBRANES ENSURE EXCELLENT FLOW RATES, BROAD CHEMICAL COMPATIBILITY, LOW PROTEIN BINDING, LOW EXTRACTABILITY, HIGH MECHANICAL STRENGTH, AND TEMPERATURE RESISTANCE IN A VARIETY OF APPLICATIONS IN THE MICROELECTRONICS INDUSTRY.

THE PES-E IS 100% INTEGRITY TESTABLE AND UTILIZES STRAINRITE’S DOUBLE RINSE PROCESS TO ENSURE EXTREMELY LOW EXTRACTABLES. POLYETHERSULFONE OFFERS A BROAD RANGE OF CHEMICAL COMPATIBILITY AND TEMPERATURE PERFORMANCE. THE PES-E MEETS USP BIOLOGICAL REACTIVITY TEST, IN VIVO FOR CLASS VI-121°C PLASTICS. STERILIZABLE USING INDUSTRY RECOGNIZED AND ACCEPTED METHODS. LEARN MORE ABOUT THE PES-E HERE. |